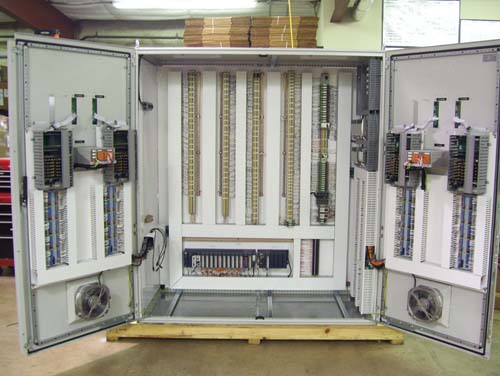

It is always better in the long run to upgrade your controls. Obsolete parts are a hassle to maintain and expensive to procure. In time upgradation not only saves you from unexpected downtimes, but also provides opportunity to improve upon machine knowledge. C&M can design a new control system to interface with your existing electrical devices or, for those with older systems that have obsolete or worn devices. We can design and build a new enclosure with all new devices.

Simple motion

Simple motion module for positioning control and synchronous control.

Advanced control but simple use as the positioning module

Speed/torque control and synchronous control are supported in addition to the traditional positioning control. Using the "simple motion module setting tool", operations such as positioning setting, monitoring and debugging can be performed easily. In addition, data synchronized with the motion controller can be collected and displayed in waveform.

●CC-Link IE Field Network connection type

QD77GF4

QD77GF8

QD77GF16

The simple motion module supports the general purpose CC-Link IE Field Network, with its flexible wiring. This module can be used as the CC-Link IE Field's master station*1 while retaining the simple motion module's functions. This realizes flexible networking supporting connection to various devices such as GOT(HMI), remote I/O, inverter, etc.

*1: QD77GF4, QD77GF8, QD77GF16 master station transmission style can use the line type or star type. Up to 104 slave devices can be connected to one network.

*2: The setting and diagnosis function using GX Works2 is disabled.

●Simple motion module SSCNET Ⅲ/H connection type

QD77MS2

QD77MS4

QD77MS16

The SSCNET Ⅲ/H connection reduces wiring, enables connections of up to 100 m between stations, and easily supports absolute position settings. The upper limit LS, lower limit LS, and near-point dog signals can be input from the servo amplifier, thus greatly reducing wiring. In addition to positioning control and speed control, processes such as synchronous control and electronic cam control can be performed.

High compatibility with conventional models, projects and sequence programs for the positioning module (QD75MH) can be used easily in the simple motion module (QD77MS) projects.

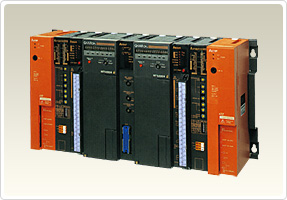

Lineup