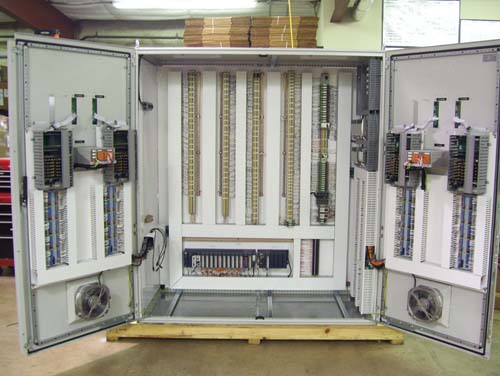

It is always better in the long run to upgrade your controls. Obsolete parts are a hassle to maintain and expensive to procure. In time upgradation not only saves you from unexpected downtimes, but also provides opportunity to improve upon machine knowledge. C&M can design a new control system to interface with your existing electrical devices or, for those with older systems that have obsolete or worn devices. We can design and build a new enclosure with all new devices.

The telecontrol communication processors offer a range of different possibilities for the implementation of extremely versatile and cost-efficient Telecontrol remote stations (RTUs) based on SIMATIC

S7-1200.

TeleControl Basic

TeleControl Basic is based on SIMATIC S7-1200 and secure transmission via mobile radio or the Internet. It is particularly suitable wherever small data quantities have to be transmitted over wireless connections or via the Internet. TeleControl Basic can be used as a low-cost fault signaling system, but thanks to the bidirectional communication facility, it is also suitable for simple telecontrol monitoring and control tasks.

Together with the GPRS communication processor, the S7-1200 CPU supports simple Telecontrol applications for monitoring and control of distributed stations using general packet radio service (GPRS). The GPRS CP 1242-7 enables SMS messaging for event driven fault diagnostics. Additional full Teleservice functionally can be realized for remote diagnostics, configuration & programming.

The CP 1243-1 communications processor is used for connecting a SIMATIC S7-1200 to the TeleControl Server Basic control center software via Ethernet and for safe communication via IP-based networks in combination with an industrial router e.g. SCALANCE M.

|

TeleControl Basic Components | |

|---|---|

|

CP 1242-7 For connection of SIMATIC S7-1200 to GSM/GPRS NET |

|

|

Order Information |

Article No. |

|

CP 1242-7 GPRS |

6GK7 242-7KX30-0XE0 |

|

CP 1243-1 For connecting SIMATIC S7-1200 to TeleControl Server Basic |

|

|

Order Information |

Article No. |

|

CP 1243-1 |

6GK7243-1BX30-0XE0 |

TeleControl Professional

The communication processors CP 1243-1 DNP3 and CP 1243-1 IEC expand the TeleControl Professional portfolio with standardized remote control protocols. Both CP 1243-1 variants offer cycle and event-driven transmission of measured values and set values as well alarms between RTU and central control system without the need for costly programming. The connection to the control station over various public or private remote networks is performed via external modems/routers such as SCALANCE M, which are connected to the Ethernet interface of the CP.

|

TeleControl Professional Components | |

|---|---|

|

CP 1243-1 DNP3 For connecting of SIMATIC S7-1200 |

|

|

Order Information |

Article No. |

|

CP 1243-1 DNP3 |

6GK7243-1JX30-0XE0 |

|

CP 1243-1 IEC for connecting SIMATIC S7-1200 |

|

|

Order Information |

Article No. |

|

CP 1243-1 IEC |

6GK7243-1PX30-0XE0 |