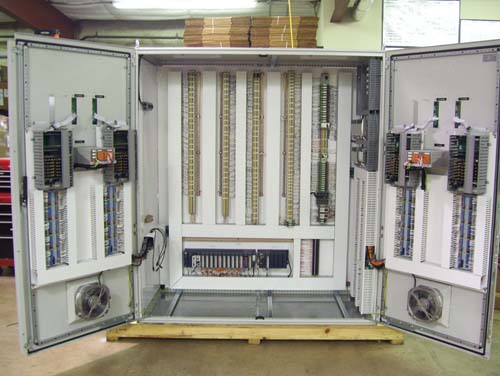

It is always better in the long run to upgrade your controls. Obsolete parts are a hassle to maintain and expensive to procure. In time upgradation not only saves you from unexpected downtimes, but also provides opportunity to improve upon machine knowledge. C&M can design a new control system to interface with your existing electrical devices or, for those with older systems that have obsolete or worn devices. We can design and build a new enclosure with all new devices.

Expanding the CPUs by using additional I/O s

The central processing units of the SIMATIC S7-1200 are designed as Compact CPUs with integrated I/Os. Their modular design can be used to increase the configuration limits or to adapt the controller to new tasks: through mounting a Signal Board on the CPU or adding separate signal modules.

Signal modules can be connected to the right of the CPU to further extend the digital or analog IO capacity. CPU 1212C accepts up to two, CPU 1214C, CPU 1215C and CPU 1217C both accept up to eight signal modules.

Signal boards can be added to the CPU to increase the number of digital or analog inputs and outputs, RS485 communication, and battery board to the controller for your application requirements without increasing the controller's footprint.

This provides users with the following advantages:

-

Optimal adjustment:

With signal modules which can be mixed as desired, users can adapt their controllers exactly to the relevant task. Modules with 8, 16 and 32 input/output channels are available. -

Flexibility:

If the task is extended subsequently, the controller can be upgraded with one of these signal modules. Updating of the user program in TIA Portal is extremely simple.