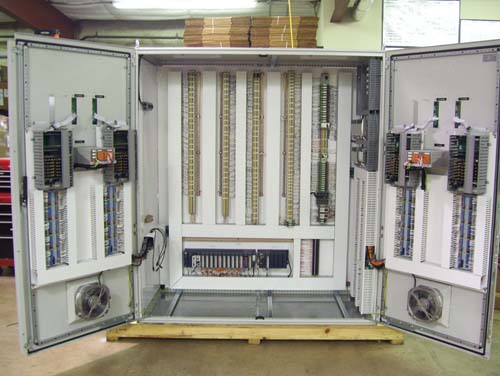

It is always better in the long run to upgrade your controls. Obsolete parts are a hassle to maintain and expensive to procure. In time upgradation not only saves you from unexpected downtimes, but also provides opportunity to improve upon machine knowledge. C&M can design a new control system to interface with your existing electrical devices or, for those with older systems that have obsolete or worn devices. We can design and build a new enclosure with all new devices.

Integrated profinet communication

|

IMATIC S7-1200 supports communication via PROFINET – the open, manufacturer-independent standard (IEC 61158/61784). PROFINET is 100% Ethernet and stands for maximum transparency, open standard communication via TCP/IP, network security and simultaneous real-time communication. The integrated PROFINET interface in SIMATIC S7-1200 can be used for programming the CPU and for communication with SIMATIC HMI Basic Panels for visualization, but also for communication with other controllers or IO devices such as drives. The PROFINET cable is connected by means of a noise-immune RJ45 port with auto-crossover functionality supporting Ethernet connections and providing data transmission rates of up to 10/100 Mbit/s. For quick and error-free installation or changes on site, with FastConnect Siemens offer a sophisticated quick-assembly system consisting of cables, plug-in connectors and assembly tools. One of the advantages, thanks to PROFINET, is the integrated Web Server of the SIMATIC S7-1200. By means of the integrated Web server, information about the CPU as well as process data can be retrieved via a standard web browser. Data can also be archived from the user program during runtime. Furthermore, in firmware version 4.0, the CPUs possess the PROFINET iDevice functionality. The simplest way to configure multiple S7-1200 CPUs into a master-slave architecture: Each CPU process image is individually written and read. |

|

Simple networking

To minimize the cabling overhead and maximize the network flexibility, the CSM 1277 compact switch module can be used for configuring a homogenous or hybrid network – in linear, tree or star topologies. The CSM 1277 is a 4-port unmanaged switch which allows you to connect the SIMATIC S7-1200 with up to three additional devices.

|

Communication module | |

|---|---|

|

CSM 1277 Compact Switch Module |

|

|

Order Information |

Article No. |

|

CSM 1277, |