CPUs for demanding tasks

There is a graded range of CPUs from the entry-level CPU right up to the high-performance CPU for configuring the controller. All CPUs control large quantity structures; several CPUs can work together in a multicomputing configuration to boost performance. Thanks to their high processing speed and deterministic response times, the CPUs enable short machine cycle times.

The different CPUs are distinguished by, for example, work memory, address range, number of connections and execution time. As well as the standard CPUs, there are also two failsafe and three fault-tolerant CPUs available.

With the Version 7 the continuous advancement of the series will be continued. Among others, storage, performance and quantity structure have been innovated. Furthermore the focus was on the new expansion of the Profinet communication performance.

The complementary systems are still the high-end controller for all industries.

Applications

-

The S7-400 is especially suitable for data-intensive tasks in the process industry. High processing speeds and deterministic response times guarantee short machine cycle times on high-speed machines in the manufacturing industry.

-

The S7-400 is used preferably to coordinate overall plants and to control lower-level systems. This is guaranteed by the high communication power and the integral interfaces.

S7-400 finds successful application here:

-

Automotive industry

-

Standard mechanical equipment manufacture incl. custom mechanical equipment manufacture

-

Warehousing systems

-

Building engineering

-

Steel industry

-

Power generation and distribution

-

Paper and printing industries

-

Woodworking

-

Textile manufacture

-

Pharmaceuticals

-

Food and beverages industries

-

Process engineering, e.g. water and wastewater utilities

-

Chemical industry and petrochemicals

Benefit

-

The power of the S7-400 is scalable thanks to a graded range of CPUs; the capacity for I/O is almost unlimited.

-

The power reserves of the CPUs enable new functions to be integrated without further hardware investment, e.g. processing of quality data, user-friendly diagnosis, integration into higher-level MES solutions or high-speed communication via bus systems.

-

The S7-400 can be structured in a modular way; there is a widely varied range of modules available both for centralized configurations and distributed structures. This results in very cost-effective spare parts handling.

-

The configuration of the distributed I/O of the S7-400 can be modified during operation (Configuration in Run). In addition signal modules can be removed and inserted while live (hot swapping).

This makes it very easy to expand the system or replace modules in the event of a fault. -

The storage of the complete project data including symbols and comments on the CPU simplifies service and maintenance calls.

-

Safety engineering and standard automation can be integrated into a single S7-400 controller;

plant availability can be increased through the redundant structure of the S7-400. -

Many of the S7-400 components are also available in a SIPLUS version for external environmental conditions, e.g. extended temperature range (-25 +60°C) and for use where there is aggressive atmosphere/condensation.

-

The high-speed backplane bus of S7-400 ensures efficient linking of central I/O modules

Design and function

The powerful backplane bus of the S7-400 and the DP communication interfaces that can be plugged directly onto the CPU allow the high-performance operation of many communication lines. This permits, for example, the division into one communications line for HMI and programming tasks, one line for high-performance and equidistant motion control components, and one "normal" I/O fieldbus.

Additionally required connections to MES-/ERP systems or the Internet via SIMATIC IT can also be implemented. The S7-400 can be expanded centrally or in a distributed configuration depending on the task. Add-on devices and interface modules are available centrally for this purpose.

Distributed expansion is possible over the PROFIBUS or PROFINET interfaces integrated in the CPUs.

If required, communication processors (CPs) can also be used.

Design

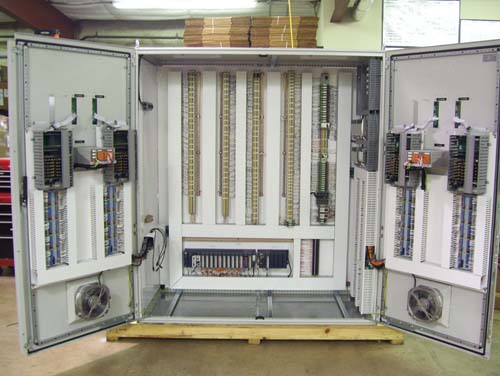

An S7-400 system basically comprises a rack, power supply, and central processing unit. It can be installed and expanded in a modular way. All modules can be positioned freely next to the power supply plugged in on the left. The S7-400 has a rugged design without a fan. Signal modules can be hotswapped. A multi-faceted module range can be used for central expansions as well as for simple configuration of distributed topologies with ET 200.

In a centralized expansion, additional mounting racks are connecteddirect to the central controller.

In addition to the standard mounting racks, aluminum mounting racks with 9 and 18 slots are also available. These aluminum racks are highly resistant to unfavorable environmental conditions, and they are more rigid and around 25% lighter.

Multicomputing

Multicomputing, that is, the simultaneous operation of several CPUs in one S7-400 central controller, offers users different benefits:

-

The overall performance of an S7-400 can be shared by means of multicomputing.

For example, complex tasks in technologies such as open-loop control, computing or communication can be split and assigned to different CPUs. Each CPU is assigned its own, local I/O for this purpose. -

Some tasks can also be disconnected from each other in multicomputing, that is, one CPU processes the time-critical process tasks and another handles the non-time-critical tasks.

In multicomputing operation, all CPUs behave like a single CPU, that is, when one CPU goes to STOP, the others are also halted. The actions of several CPUs can be coordinated selectively by instruction via synchronization calls.In addition, data exchange between the CPUs takes place at an extremely high speed via the "global data" mechanism.

Data/program memory

The size of the work memory is determined CPU that can be selected from a finely graded range of CPUs.The integral load memory (RAM) is sufficient for small to mediumsized programs.

For larger programs, the load memory is enlarged by plugging in RAM or FEPROM memory cards

(64 KB to 64 MB).

Special functions

The S7-400 CPUs have some highly useful special functions:

-

Simpler and faster upgrade due to firmware update via network from an engineering workstation

-

Additional write-protection (for e.g. no component download from PC to CPU) via a system function

-

Optional know-how protection by reading the serial number of the memory card, so that it is ensured that the program runs only with the particular memory card

An integrated data record gateway permits integrated accessto data records across different bus systems and networkboundaries e.g. a control-level PC can communicate via PROFINETwith a lower-level S7-400 controller and the field devicesconnected to it via PROFIBUS.