S7-300 Signal modules

Description

Digital actuators and sensors can be connected to a SIMATIC S7-300 via digital modules. The extensive range of modules allows the most suitable signal module to be selected in each case.

Area of application

Digital input/output modules contain digital inputs/outputs for the automation system. Digital sensors and actuators can be connected to the automation system via these modules. Switches and 2-wire proximity switches (BEROs) can be connected to input modules, for example. Output modules are suitable for connection of solenoid valves, contactors, small motors, lamps and motor starters.

Benefits

The use of digital input/output modules provides the user with the following advantages:

-

Optimum adaptation;

since almost any combination of modules is possible, the number of inputs/outputs can be matched to suit the task in hand. Superfluous investments no longer exist -

Flexible process connection;

the wide variety of digital actuators and sensors facilitates connection of the automation system to the process

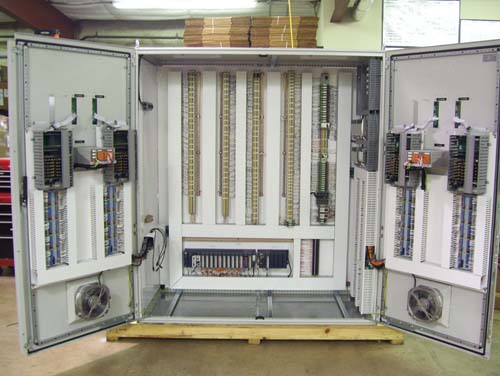

Design and functions

Digital input/output modules exhibit the following mechanical characteristics:

Compact design

The rugged plastic housing features:

• Green LEDs for displaying the signal states at the inputs/outputs

• Slot for the front connector, protected by the front cover

• Labeling area on the front cover

Easy assembly

The modules are mounted on DIN rails and connected to adjacent modules via bus connectors. There are no slot rules, the input addresses are determined by the slots.

When used in the ET 200M distributed I/O station together with active bus modules, the modules can be hot-swopped during operation without affecting the other modules.

User-friendly wiring

The modules are wired by means of a front connector. When they are first plugged in, a coding element clicks into place so that the connector will only fit into modules of the same type. When the module is replaced, the front connector can be used in its fully-wired state for a new module of the same type.

SM 321 Digital Input Modules

SIMATIC S7-300, Digital input SM 321, isolated, 16 DI, 24 V DC, 1x 20-pole

SIMATIC S7-300, Digital input SM 321, isolated, 16 DI, 24 V DC, 1x 20-pole, 0.05 ms input delay

SIMATIC S7-300, Digital input SM 321, Isolated 16 DI, 24 V DC, Source input, 1x 20-pole

SIMATIC S7-300, Digital input SM 321, Isolated 32 DI, 24 V DC, 1x 40-pole

SIMATIC S7-300 digital input SM 321, Isolated in groups of 16, 64 DI, 24 V DC, 3ms, Sink/source input Terminal blocks 6ES7392-1.N00-0AA0 and cable 6ES7392-4...0-0AA0 required

SIMATIC S7-300, Digital input SM 321, isolated, 16 DI, 24-48 V AC/DC with single rooting, 1x 40-pole

SIMATIC S7-300, Digital input SM 321, isolated, 16 DI, 48-125 V DC, 1x 20-pole

SIMATIC S7-300, Digital input SM 321, isolated, 32 DI, 120 V AC, 1x 40-pole

SIMATIC S7-300, Digital input SM 321, isolated, 8 DI, 120 V/230 V AC, 1x 20-pole

SIMATIC S7-300, Digital input SM 321, isolated, 8 DI, 120 V/230 V AC, 1x 40-pole, with single rooting/channel

SIMATIC S7-300, Digital input SM 321, Isolated 16 DI, 120/230 V AC, 1x 20-pole

SIMATIC S7-300, Digital input SM 321, isolated, 16 DI; 24 V DC, 1x 20-pole, process interrupt, diagnostics, suitable for isochronous mode

SM 322 Digital Output Modules

SIMATIC S7-300, Digital output SM 322, isolated, 8 DO, 24 V DC, 2A, 1x 20-pole

SIMATIC S7-300, Digital output SM 322, isolated, 16 DO, 24 V DC, 0.5A, 1x 20-pole, Total current 4 A/group (8 A/module)

SIMATIC S7-300, Digital output SM 322 High Speed, isolated, 16 DO, 24 V DC, 0.5A, 1x 20-pole

SIMATIC S7-300, Digital output SM 322, isolated, 32 DO, 24 V DC, 0.5A, 1x 40-pole, Total current 4 A/group (16 A/module)

SIMATIC S7-300 digital output SM 322, Isolated in groups of 16, 64DO, 24 V DC, 0.3A sink output Total current 2 A/group, 8 A/module Terminal blocks 6ES7392-1.N00-0AA0 and cable 6ES7392-4...0-0AA0 required

SIMATIC S7-300 digital output SM 322, Isolated in groups of 16, 64DO, 24 V DC, 0.3A source output Total current 2 A/group, 8 A/module Terminal blocks 6ES7392-1.N00-0AA0 and cable 6ES7392-4...0-0AA0 required

SIMATIC S7-300, Digital output SM 322, isolated, 8 DO, 48-125 V DC, 1.5A, 1x 20-pole

SIMATIC S7-300, Digital output SM 322, isolated, 8 DO, 120/230 V AC, 1 A, 1x 20-pole

SIMATIC S7-300, Digital output SM 322, Isolated 16 DO, 120/230 V AC, 1 A, 1x 20-pole

SIMATIC S7-300, Digital output SM 322, isolated, 32 DO, 120 V/230 V AC, 1 A, double-width, 2x 20-pole

SIMATIC S7-300, Digital output SM 322, isolated, 8 DO (relay), 1x 20-pole, 24 V DC, 2 A or 230 V AC, 2A

SIMATIC S7-300, Digital output SM 322, isolated, 8 DO (relay), 1x 40-pole, 24 V DC, 5 A or 230 V AC, 5 A, connectors with spring-loaded terminal can be used as of 6ES7392-1BM01-0AA0

SIMATIC S7-300, Digital output SM 322, Isolated 16 DO, relay contacts, 1x 20-pole

SIMATIC S7-300, Digital output SM 322, isolated, 8 DO, 120/230 V AC, 2A, with single rooting/channel and selectable failure mode, 1x 40-pole

SIMATIC S7-300, Digital output SM 322, isolated, 16 DO (solid-state relay), 24-48 V AC/DC; 0.5 A with single rooting, 1x 40-pole

SIMATIC S7-300, Digital output SM 322, isolated, 8 DO (relay), 1x 40-pole, 24 V DC, 120-230 V AC, 5 A with RC filter overvoltage protection

SIMATIC S7-300, Digital output SM 322, isolated, 8 DO, 24 V DC, 0.5A (1x 8 DO), Short-circuit protection diagnostics, 1x 20-pole

SM 323 SM 327 Digital IO

SIMATIC S7-300, Digital module SM 323, isolated, 8DI and 8DO, 24 V DC, 0.5 A Total current 2A, 1x 20-pole

SIMATIC S7-300, Digital module SM 323, isolated, 16 DI and 16 DO, 24 V DC, 0.5 A, Total current 4A, 1x 40-pole

SIMATIC S7-300, Digital module SM 327, isolated, 8DI and 8DX, 24 V DC, 0.5 A 1x 20-pole; 8DX by individual channels Can be parameterized as DI or DO