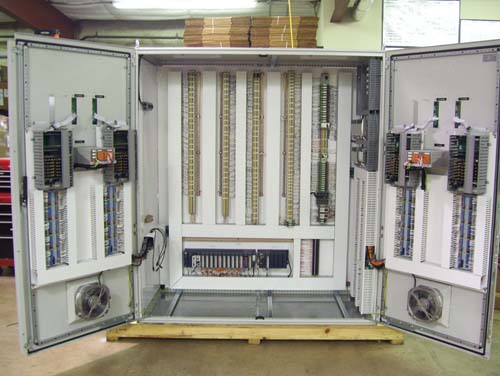

It is always better in the long run to upgrade your controls. Obsolete parts are a hassle to maintain and expensive to procure. In time upgradation not only saves you from unexpected downtimes, but also provides opportunity to improve upon machine knowledge. C&M can design a new control system to interface with your existing electrical devices or, for those with older systems that have obsolete or worn devices. We can design and build a new enclosure with all new devices.

|

Standard CPUs | |

|---|---|

|

CPU 1511-1 PN for small to medium applications • Integrated display |

|

|

Order Information |

Article No. |

|

CPU 1511-1PN |

|

|

CPU 1513-1 PN for medium applications • Integrated display |

|

|

Order Information |

Article No. |

|

CPU 1513-1 PN |

|

|

CPU 1515-2 PN for medium to exceptionally demanding applications • Integrated display |

|

|

Order Information |

Article No. |

|

CPU 1515-2 PN |

|

|

CPU 1516-3 PN/DP for exceptionally demanding applications and additional communication tasks • Integrated display |

|

|

Order Information |

Article No. |

|

CPU 1516-3 PN/DP |

|

|

CPU 1517-3 PN/DP for demanding applications and additional communication tasks • Integrated display |

|

|

Order Information |

Article No. |

|

CPU 1517-3 PN/DP |

|

|

CPU 1518-4 PN/DP for high-performance applications and shortest reaction times • Integrated display |

|

|

Order Information |

Article No. |

|

CPU 1518-4 PN/DP |